Gheni, Ahmed1; ElGawady, Mohamed2 and Myers, John3

1 PhD candidate, Civil, Department of Civil, Architectural & Environmental Engineering, Missouri University of Science and Technology, 1401 N. Pine Street, aagmr6@mst.edu

2 Benavides Associate Professor, Department of Civil, Architectural & Environmental Engineering, Missouri University of Science and Technology, 1401 N. Pine Street, elgawadym@mst.edu

3 Professor and Associate Dean, Department of Civil, Architectural & Environmental Engineering, Missouri University of Science and Technology, 1401 N. Pine Street, jmyers@mst.edu

ABSTRACT

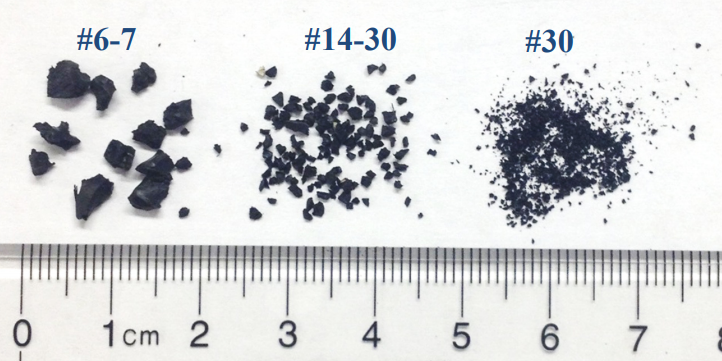

The low thermal insulation capacity of concrete masonry blocks motivated the researchers to investigate the impact of adding recycled crumb rubber that came from scrap tires as an aggregate replacement in the concrete masonry unit production. Using the scrap tire rubber produced more sustainable construction units by using recycled materials and reduce the buildings energy consumption. An experimental investigation was conducted to explore the energy efficiency and thermal characterization effects of adding different ratios of crumb rubber as an aggregate replacement to concrete masonry units. Two different tests were performed, according to both ASTM standards C1363–11 and D5334–14, to find the thermal conductivity factor, energy saving, and thermal insulation for the whole masonry units and the new material itself. A guarded hot box was fabricated to simulate a real insulation case. The results indicated that adding the crumb rubber to masonry units had a positive impact on the energy saving. Units with 37% rubber replacement ratio reduced the energy consumption by 48% compared to a conventional masonry unit. A modified thermal needle probe procedure was used to find the thermal conductivity of the rubberized masonry blocks as a material, not a unit. The new rubberized material exhibited a remarkable reduction in thermal conductivity compared to many commonly used standard construction materials. The mechanical characterization and dimension requirements were reported to show that the new eco-friendly masonry units met the ASTM requirements for load-bearing concrete masonry units.

056