Y.Liu1, J. Dawe2 and G. Christie3

- Assistant Professor, Dept of Civil Engineering, Dalhousie University, 1360 Barrington St, Halifax, NS, B3J 1Z1 yi.liu@dal.ca

- Professor, Dept of Civil Engineering, University of New Brunswick, Fredericton, NB, E3B 5A3, Dawe@unb.ca 3 Undergraduate student, Dept of Civil Engineering, University of New Brunswick

ABSTRACT

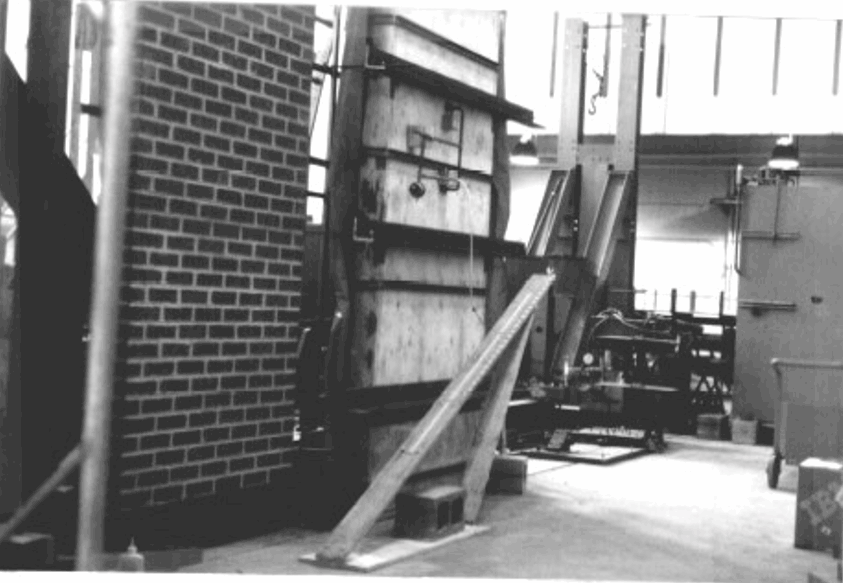

Lightweight sawdust concrete blocks manufactured entirely on an ad hoc basis from indigenous materials using only a hand-made steel plate mould were evaluated. These units were manufactured by combining locally available materials such as pit-run sand and clay, and untreated wood sawdust with cement and water. Consequently, these units exhibited a low compressive strength that would most likely make them unsuitable for hollow load-bearing masonry. However, when completely filled with a 25 MPa grout, two-high prisms exhibited an ultimate strength of approximately 16 MPa. Apart from this, it was found that these rather crudely manufactured units displayed some rather interesting characteristics that merit research in addition to the initial research present herein. The units, measuring 600 x 300 x 140 mm, while approximately equal to the weight of a standard 400 x 200 x 140 mm CMU, provide 2.25 times the wall surface area of the standard unit and require only 1.8 times the amount of mortar to fully install. Besides having advantageous properties relating to saw-cutting, nailing and screw attachments, it was found that hollow walls made of these units provide a brick veneer back-up as good as, or better than that provided by light gauge cold-formed steel studs.

KEYWORDS: lightweight, sawdust aggregate, brick veneer back-up

3a-2