Amro Mahmoud, Baher Haleem, Saeid Ghasemalizadeh, Hasini Rathnayake, and Nigel Shrive

i M.Sc. student, University of Calgary, Calgary, Canada, amro.mahmoud@ucalgary.ca

ii Ph.D. candidate, University of Calgary, Calgary, Canada, baher.haleem@ucalgary.ca

iii Ph.D. candidate, University of Calgary, Calgary, Canada, saeid.ghasemalizadeh@ucalgary.ca

iv Postdoctoral associate, University of Calgary, Calgary, Canada, hasini.rathnayake@ucalgary.ca

v Professor Emeritus, University of Calgary, Calgary, Canada, ngshrive@ucalgary.ca

ABSTRACT

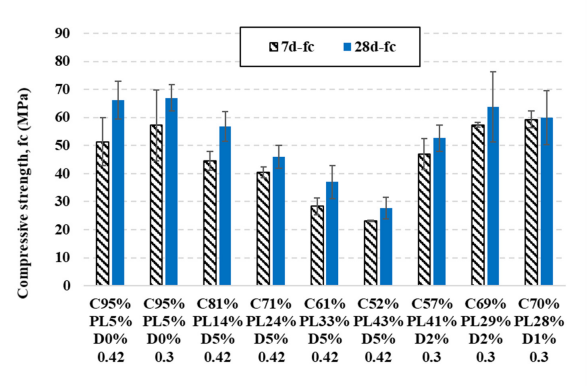

The Portland cement (PC) industry significantly contributes to global CO2 emissions, accounting for 5% to 8% of annual anthropogenic emissions. Supplementary cementitious materials (SCMs) offer sustainable alternatives that reduce the environmental impact of PC concrete. Still, the increased cost of conventional SCMs due to industry changes has created a need for more cost-effective solutions. Pulverised limestone (PL) has emerged as a promising alternative due to its abundance and cost-efficiency. While PL can reduce clinker by up to 15% in North America and 35% in Europe, it often leads to a significant decrease in compressive strength. Recent studies suggest that the ideal clinker replacement is around 12% by weight, beyond which strength is compromised. To produce eco-friendly concrete block, in this study, a new proprietary mineral admixture called Duraflex was assessed for its potential to maintain strength in cementitious pastes with higher PL content. Duraflex has previously shown promise in improving soil stabilization by enhancing strength and reducing porosity. The findings indicate that small amounts of Duraflex (2%) can effectively retain strength in cement mixes containing up to 30% PL, surpassing the performance of conventional SCMs. While PL replacement beyond 12-15% generally reduces strength, Duraflex mitigates this effect, allowing for greater clinker reduction without sacrificing performance. The study shows that using 30% PL with 2% Duraflex could reduce greenhouse gas (GHG) emissions by up to 20% compared to current Portland Limestone Cement formulations, which achieve a 10% GHG reduction with lower strength. This research highlights the potential of combining PL with Duraflex as a sustainable and cost-efficient approach to reducing clinker content while maintaining concrete strength and workability and lowering carbon emissions. In addition, an alternative approach to the problem is shown to be almost ready to be transferred to industry.

KEYWORDS: compressive strength, concrete masonry units, duraflex, granulated blast furnace slag (GBFS), portland cement, pulverised limestone.

047-Mahmoud.pdf