Shanjida Khan, Ali Teymouri, Saeid Ghasemalizadeh, and Rahil Khoshnazar

i M.Sc. Student, University of Calgary, Calgary, Canada, shanjida.khan1@ucalgary.ca

ii PhD Candidate, University of Calgary, Calgary, Canada, ali.teymouri@ucalgary.ca

iii Postdoctoral Researcher, University of Calgary, Calgary, Canada, saeid.ghasemalizadeh@ucalgary.ca

iv Associate Professor, University of Calgary, Calgary, Canada, rahil.khoshnazar@uca

ABSTRACT

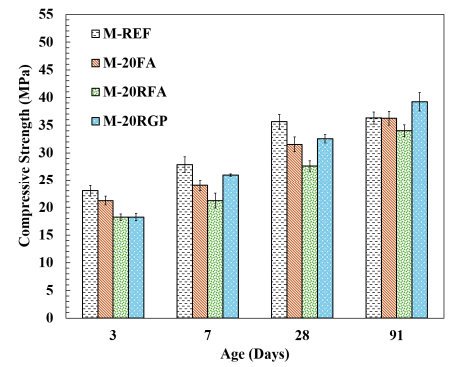

Portland cement plays a major role in concrete masonry units (CMUs) as a binding agent; however, cement production contributes to high amounts of greenhouse gas emissions. A widely adopted strategy for reducing such emissions is the use of supplementary cementitious materials (SCMs) as partial replacements for cement. However, the increasing scarcity of conventional SCMs, such as fly ash and slag, has necessitated the need to explore alternative SCMs (ASCMs). Therefore, this research aims to compare the effects of two ASCMs, namely reclaimed fly ash (RFA) and recycled glass powder (RGP), on the properties of cementitious mixtures. Cement paste and mortar samples with 20 wt% cement replacement by these ASCMs were prepared, and tested for rheology, heat of reactions, flow table, and compressive strength development. The results were compared to a reference sample containing 100 wt% cement and a sample with 20 wt% cement replacement with Class F fly ash (FA). The results showed that the RFA did not considerably affect the flowability of cementitious mixtures as determined by the apparent viscosity of the pastes and flow table measurements of the mortars. Incorporating RGP slightly increased these parameters compared to the reference samples made with only cement. The total heat evolution of the pastes incorporating these ASCMs over the 7-day testing period was lower than that of the reference, with the heat of the paste with RGP being marginally higher than that of RFA and FA. The mortars with RFA and RGP had reduced compressive strength at early ages, however, this diminished by 91 days, when compared to the reference mortar and that with FA. These findings provide a basis for implementation of these ASCMs into CMUs to reduce their cement content while maintaining or improving their mechanical properties, contributing to the development of low-carbon CMUs.

KEYWORDS: alternative supplementary cementitious materials, cement mortar, compressive strength, heat of reaction, rheology.

052-Khan.pdf