Mathavanayakam Sathurshan; Hossein Derakhshan; Julian Thamboo; Jack Gill; Cathy Inglis; Tatheer Zahra

i PhD Candidate, School of Civil & Environmental Engineering, Queensland University of Technology, Brisbane, QLD 4000, Australia, sathurshan.mathavanayakam@hdr.qut.edu.au

ii Senior Lecturer, School of Civil & Environmental Engineering, Queensland University of Technology, Brisbane, QLD 4000, Australia, hossein.derakhshan@qut.edu.au

iii Senior Lecturer, Department of Civil Engineering, South Eastern University of Sri Lanka, 32360 Oluvil, Sri Lanka, jathamboo@seu.ac.lk

iv General Manager, Concrete Masonry Association Australia (CMAA), NSW, Australia, jack.gill@thinkbrick.com.au

v Group CEO, Concrete Masonry Association Australia (CMAA), NSW, Australia, cathy@thinkbrick.com.au

vi Senior Lecturer, School of Civil & Environmental Engineering, Queensland University of Technology, Brisbane, QLD 4000, Australia, t.zahra@qut.edu.au

ABSTRACT

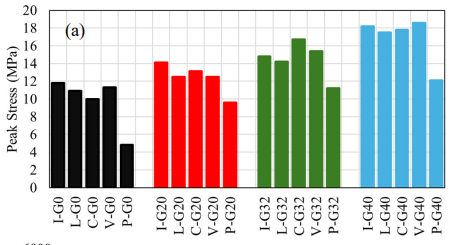

Interlocking dry-stack masonry has shown to accelerate the wall construction compared to conventional mortared masonry, however the widespread adaptation of interlocking dry-stack masonry is hindered due to the lack of design provisions. The compressive strength and stress-strain behaviour of dry-stack masonry should be known to appropriately design such walling systems. In this study, an experimental campaign was conducted to understand the compressive behaviour of dry-stack concrete masonry. To this end, five different interlocking dry-stack concrete blocks were acquired from across Australia. These blocks were used to construct either four- or five-course high, dry-stack concrete masonry wallettes with and without core fill grouting. In total, 80 wallettes were tested with strength of core-filled grout being varied from 20 MPa to 40 MPa. The results have been analysed in terms of failure patterns, compressive strength, and deformation characteristics. The results showed that the grouted dry-stack concrete masonry wallettes exhibited similar failure patterns as those of conventional grouted concrete masonry, which has mortar joints. The average axial compression strengths of tested grouted dry-stack wallettes ranged between 9.6 and 18.6 MPa, whereas the ungrouted wallettes varied from 4.8 to 11.8 MPa. The grouted dry-stack concrete masonry demonstrated better performance than the ungrouted dry-stack concrete masonry in terms of stiffness and load carrying capacity. The grouted wallettes exhibited higher strength, deformation capacity, and elastic moduli with increasing grout strength.

KEYWORDS: Dry-stack masonry, Concrete blocks, Axial compression behaviour, Grout, Stress-strain behaviour.

099-Sathurshan.pdf