Craig Walloch, Pranav Pradeep Kumar, Nicholas Lang, Randolph Kirchain, and Hessam Azarijafari

i Director of Materials Science, Concrete Masonry and Hardscapes Association (CMHA), Herndon, VA, United States, cwalloch@masonryandhardscapes.org

ii Postdoctoral Associate, MIT Concrete Sustainability Hub (CSHub), Department of Civil and Environmental Engineering, Massachusetts Institute of Technology, Cambridge, MA, United States, pranavpk@mit.edu

iii Vice President Engineering & Advocacy, Masonry, Concrete Masonry and Hardscapes Association (CMHA), Herndon, VA, United States, nlang@masonryandhardscapes.org

iv Principal Research Scientist Materials Research Laboratory and Director MIT Concrete Sustainability Hub (CSHub), Massachusetts Institute of Technology, Cambridge, MA, United States, kirchain@mit.edu

v Deputy Director MIT Concrete Sustainability Hub (CSHub) and Executive Director, MIT Electron Conducting Carbon Cement-Based Materials (ec^3) Hub, Massachusetts Institute of Technology, Cambridge, MA, United States, hessam@mit.edu

ABSTRACT

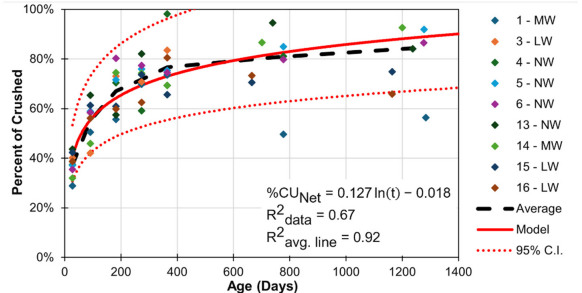

Accurate quantification of the natural carbon sequestration of dry-cast manufactured concrete products is crucial for assessing their long-term environmental impact. Previously, test protocols for measuring carbon sequestration in manufactured dry-cast concrete products were developed, and the results on the amount and rate of sequestration of nine sets of concrete masonry units (CMU) from 1 to 6 months of age were reported. This paper presents a follow-up study that extends the analysis on the same nine sets of units to a 3-year period. Furthermore, experimental tests using crushed samples of the nine sets, exposed to the atmospheric conditions, provide an estimate of the maximum carbonation potential for dry-cast concrete. The results demonstrate that initial drying conditions during sample preparation play a crucial role in carbon uptake for dry-cast CMUs, with specimens dried at 45°C showing higher uptake at 28 days due to residual moisture enabling additional carbonation. However, this effect was not observed at 91 and 182 days, indicating that residual moisture’s influence decreases over time. Additionally, crushed CMU samples reached a practical upper limit of 52%-55% of the maximum calcination carbon emission potential after four months of exposure. A proposed logarithmic model effectively captures the observed carbon uptake trends, aligning with the deceleration of carbonation over time due to pore blocking and the limited availability of reactive phases.

KEYWORDS: carbon uptake modeling, carbonation potential, CO2 uptake modeling, concrete masonry unit (CMU), dry-cast, sequestration.

152-Walloch.pdf