Nascimento, Marcio R.1; Fonseca, Fernando S.2 and Roman, Humberto R.3

1 Assistant Professor, Catholic University of Santa Catarina, Civil Engineering Department, Joinville, Brazil,

2 Associate Professor, Brigham Young University, Department of Civil and Environmental Engineering, Provo, Utah, fonseca@byu.edu

3 Professor, Federal University of Santa Catarina, Civil Engineering Department, Santa Catarina, Brazil, humberto.roman@ufsc.br

ABSTRACT

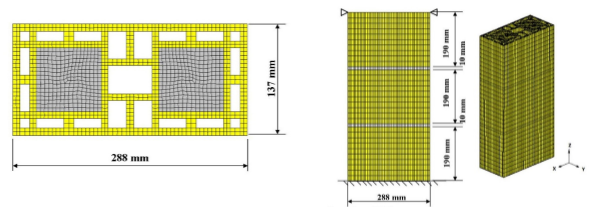

Grouting is a way to increase the compressive capacity of masonry systems and, when necessary, a way to bond reinforcement to masonry units. Masonry grout is typically a mixture of Portland cement and aggregates. For some applications, many masonry standards allow the replacement of traditional masonry grout by mortar. Although the Brazilian technical standard for clay masonry allows mortar to be used as grout, there is a lack of research to support such a provision. A comprehensive experimental and analytical study, therefore, has been conducted to determine the capacity and evaluate the behavior of clay block prisms filled with mortar. One type of clay block and six types of mortar were used to construct hundreds of prisms, which were then tested to failure. The experimental results indicate the viability of using mortar as replacement for typical masonry grout. This article presents the analytical part of the study to evaluate the mechanical behavior of clay block prisms filled with mortar. Analyses were conducted using a generalpurpose, nonlinear finite element software that simulates structural behavior under different loading scenarios. A three-dimensional model of the prisms was developed using 8-node brick elements for both block and mortar with non-linear properties assigned to each material. The model was validated using the experimental data and then used to determine the contribution of each prism component in resisting the applied load. The stresses at different location along the thickness, width, and height of the prisms were also computed. The calculated stresses indicated reasonably well the stresses at which either the blocks would fail in tension or the mortar at the joints would fail in compression.

KEYWORDS: structural masonry, grouting, grout, mortar, FEA, analysis, stress, strain, deformation

006