Heidi Jandris

i Technical Services, Jandris Block, Gardner, Massachusetts, heidi@ajandris.com

Owner, 4-KORE Consulting, Worcester, Massachusetts, heidi@4-kore.com

ABSTRACT

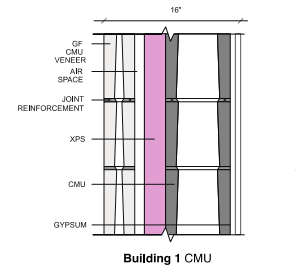

The primary goal of this investigation is to provide a comparative embodied carbon cradle-to-gate (A1-A3) LCA (Life Cycle Analysis). Three different prototype buildings are compared: a CMU (Concrete Masonry Unit) structure with architectural CMU veneer, a wood and steel light frame podium-style building with metal panel rainscreen, and an insulated precast panel concrete building with a thin brick veneer. This study incorporates recent carbon sequestration research for the CMU. Due to the unique structure of dry-cast concrete products, a relatively large amount of carbon dioxide is sequestered at significantly faster rates within the first 28 days of manufacture when compared with other types of wet-cast concretes. This timeframe is considered to be within A1-A3 for concrete masonry unit manufacturing. Building elements included in this LCA are the foundation, beams and columns, exterior walls, and stairwells/shafts. The secondary goal of this study is to serve as a frame of reference to use when evaluating the embodied carbon of CMU structures and making comparisons. It can also serve as a roadmap for LCA practitioners, providing guidance for how to evaluate the embodied carbon of masonry components such as mortar, grout, and how to calculate the volume of units used. The tertiary goal of this study is to serve as a starting point for future embodied carbon Whole Building LCA studies incorporating use stage scenarios. Examples of this are demonstrating how masonry structures can lower use phase embodied carbon with low maintenance requirements, less replacement due to durability and inherent resiliency, and incorporating carbon sequestration that occurs during the building’s use stage and beyond. Such analysis can also be used in conjunction with energy modeling to demonstrate how operational carbon can be lowered by accounting for concrete masonry’s inherent thermal mass. The findings of this study show that conventional concrete masonry construction has only 6% more embodied carbon compared to the wood and steel light frame prototype, whereas the precast prototype contained 51% more embodied carbon than the wood and light frame building. These comparative values do not take into consideration the additional carbon sequestration that would be realized during the use phase of the concrete structures.

KEYWORDS: Concrete masonry, embodied carbon, dry-cast concrete, sequestration, LCA, Life Cycle Analysis, A1-A3, Global Warming Potential.

051-Jandris.pdf