Saeid Ghasemalizadeh and Rahil Khoshnazar

i Postdoctoral Researcher, University of Calgary, Calgary, Canada, saeid.ghasemalizadeh@ucalgary.ca

ii Associate Professor, University of Calgary, Calgary, Canada, rahil.khoshnazar@ucalgary.ca

ABSTRACT

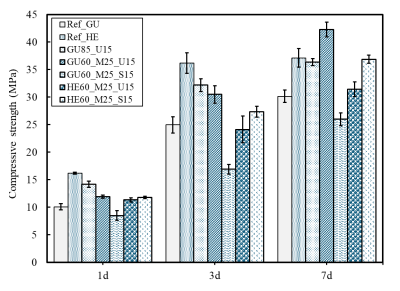

Concrete block masonry units (CMUs) are widely used around the world in construction practices. CMUs mainly rely on Portland cement (PC) to develop compressive strength. Production of PC, however, is a significant source of greenhouse gas (GHG) emissions, emphasizing the need for methods to reduce the carbon footprint of CMUs. A practical and effective approach to reduce the carbon footprint of concrete products is partially substituting PC with supplementary cementitious materials (SCMs). However, the extent of PC substitution with SCMs in CMUs has remained limited as it adversely affects the strength development of the CMUs, where achieving a high early-strength is crucial. It is therefore necessary to develop methods to benefit from higher quantities of SCMs in CMUs without compromising their strength development. This study focuses on the utilization of ultrafine slag (UFS), instead of ordinary slag, in combination with a locally available medium-grade metakaolin (MK) to replace up to 40 wt% of PC in cementitious mixtures. Combinations of MK-UFS, and MK-slag were used to substitute 40 wt% of type GU and HE cement in mortar samples. The superplasticizer demand of the mortars and their compressive strength for up to 7 d were recorded. The results were then compared with those obtained for mortars prepared with only GU or HE cement. Selected blends were then used in preparing dry concrete mixtures which were tested for the compressive strength at the ages of 3 and 7 d. The results of mortar samples showed that replacing 40 wt% of GU cement with MK-UFS blend resulted in mortar samples with a higher compressive strength compared to that made with 100 wt% GU cement starting from 1 d, however, such an enhancing effect was not observed when the UFS-MK blend was used to replace the same content of HE cement. The dry concrete mixture made with 60 wt% GU cement and 40 wt% UFS-MK blend achieved a 7-d compressive strength of higher than 50 MPa, showing promising results for application in high-strength CMU production.

KEYWORDS: Supplementary cementitious materials, Slag, Metakaolin, Compressive strength, Concrete block masonry Unit.

153-Ghasemalizadeh.pdf