Construction Practices

This is part of a larger series of practical posts addressing common questions and concerns regarding masonry construction. These are meant to be accessible articles for contractors and design practitioners which shed some light on masonry topics, including relevant codes and standards provisions that can be applied to the topic at hand.

When evaluating workmanship, what are reasonable expectations involving coursing?

Offering some guidance on what to focus on, and what to leave in the hands of the contractor

CMDC would like to acknowledge the AEMQ technical committee for sharing the initial seed document for these Construction Practices

Coursing – More difficult than it looks!

One of the great secrets of an experienced mason is proper coursing. Over years of training, a mason learns to lay bricks true to a line, to ensure proper alignment of horizontal mortar joints, to align vertical arises, and to keep their work plumb, within the applicable tolerances. Although individual bricks and blocks contain imperfections and have some variability in their dimensions, the finished work of a skilled mason will give the illusion of a perfect grid. In fact, minor adjustments to the thickness of mortar joints are required throughout the work to keep things looking straight, this includes carefully controlling the thickness horizontal bed joints to properly fill the required space with masonry and minimize unnecessary cutting of units.

How can masons align masonry joints with parts of the building using coursing?

Coursing consists of carefully controlling the thickness of the mortar joints to ensure joint thicknesses appear equal over the height of a wall. Proper coursing must also allow the wall to reach the predetermined height while accounting for variability in the dimensions of the masonry units themselves.

A few basic rules must be followed to achieve proper coursing:

- Meet the tolerance requirements in accordance with the applicable Code or Standard

- Maintain the horizontal alignment of the joints, within the applicable tolerances

- Account for alignment with the top of openings and reaching the bottom of the soffit, lintel, or shelf angle above

- Avoid the need to cut units to complete the masonry work

Good planning and careful attention to the exact dimensions of the area that will receive the masonry are both critically important. Although dimensions may be stated in building drawings, the actual conditions of the site, as well as the true dimensions of the units used, may vary and will have an impact on the coursing requirements. This is particularly true when installing masonry veneers and partition walls that will remain apparent, which must be installed around existing portions of the structure. Structural concrete, steel, and wood framing standards are constructed to tolerances that can be quite different from standard masonry tolerance.

Masonry Requirements for coursing

Mortar joints typically have a specified thickness of 10 mm with a tolerance of ± 3 mm, as per the requirements of CSA A371-14 (see clauses 6.2.2.2.6 and 7.1.2.1). For small residential buildings constructed in accordance with Part 9 of the Building Code, a less restrictive tolerance of ± 5 mm applied (see clause 9.20.4.1 of NBCC 2015). However, industry standards dictate that variations in mortar joint thickness should not be noticeable by a person standing 6 m away from the finished work (see note in clause 7.1 of CSA A371-14). Since the building foundation or other support on which the masonry is constructed can be rough or imperfectly leveled, mortar joint thickness below the first course is allowed more variability. CSA A371-14 allows the first mortar joint to be between 6 and 20 mm thick, or 0 to 13 mm thick for masonry on a shelf angle or lintel (see clause 7.1.2.2).

It should be noted that the above requirements apply to “unit masonry construction” (concrete, fired clay or silicate bricks that are at lease 75 mm thick and at most 200 mm tall and 400 mm long). Different mortar joint thicknesses and tolerances may apply for stone or thin masonry veneers, or for certain special applications with unit masonry. When a project calls for masonry other than “unit masonry”, clear requirements for the joint thickness and tolerances should be provided by the designer.

Coursing of bricks and blocks

The approach to coursing must comply with the applicable restrictions and requirements of the standards. Although a few mm of tolerance between masonry courses is not much to play with, those minute adjustments can make a big difference for efficient material usage. When metric modular units are used, a mason will have ample courses of masonry to distribute the minor adjustments. When using concrete blocks, however some cuts may be inevitable.

Determining the coursing height for metric concrete block masonry units is generally rather simple. Since standard concrete blocks are all 190 mm in height, the height of one course plus a mortar joint should be 200 mm. As the mason builds the wall, the top of each course should land on increments of 200 mm. If the height of the finished work is not a multiple of 200 mm, then the height of each course can be adjusted progressively by a few mm more or a few mm less as the wall is constructed. Metric modular bricks have a height of 57 mm, such the height of three courses (including mortar joints) add up to 200 mm. This allows the mason to keep track of the height of his works and make minor adjustments to arrive at the correct height for the finished work.

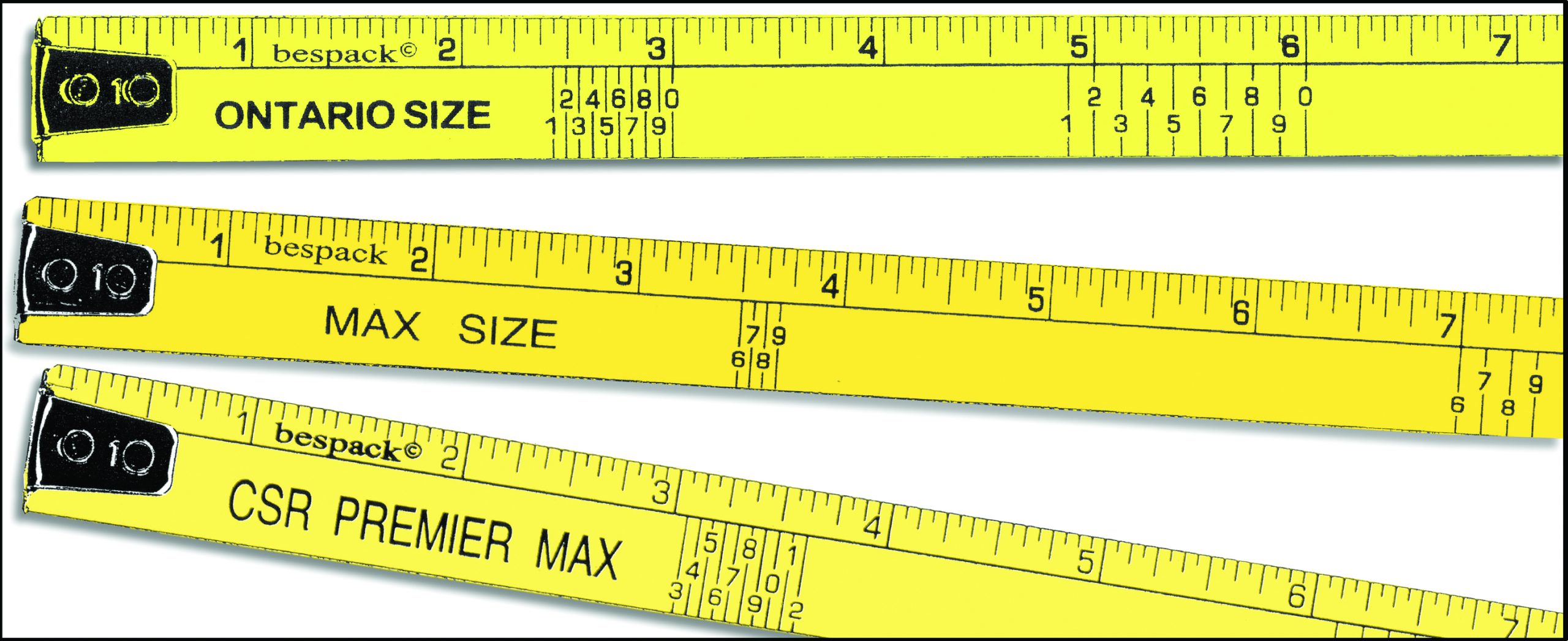

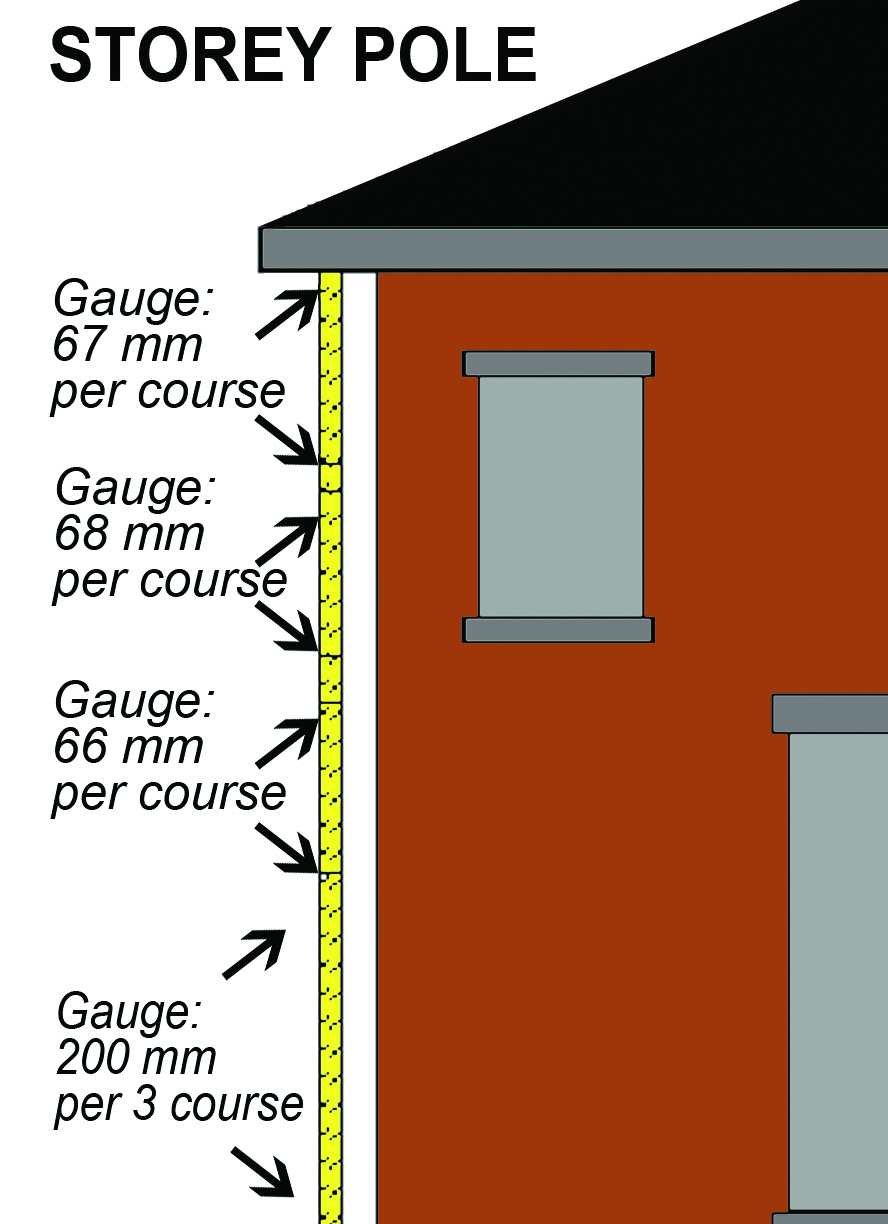

There is a wide variety of bricks on the marked, with different over-all dimensions and different heights. Some manufacturers provide coursing charts to help the mason determine the expected heigh of a given number of courses, for a given mortar joint thickness. Coursing is sometimes laid out by making marks on a guidepost and some masons use special gauge tapes; however, most often a combination of experience, visual assessments, a regular measuring tape and some quick mental math will keep a mason’s coursing even from the bottom to the top of a wall.

There are tools available to simplify this process including specialized tape measures and devices (storey poles or “speed poles”) meant to assist with placing leads along building corners (typically seen in residential construction).

Final Thoughts

Whichever approach is used to keep the coursing on point, the skilled hands of a qualified mason achieve an even aesthetic for the masonry walls they construct. Although some may view tolerances as a way of allowing certain errors in construction, masonry tolerances generally allow a mason to enhance the appearance of their works by evenly filling a wall with uniformly space units, compensating for manufacturing tolerances, and minimize unsightly and unnecessary cut bricks and blocks.