Mark D. Hagel

i Executive Director, Alberta Masonry Council, Alberta, Canada, markhagel@albertamasonrycouncil.ca

ABSTRACT

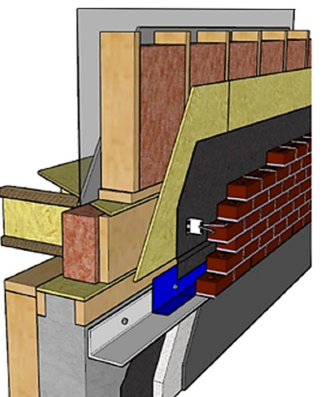

Shelf angle design represents the intersection of masonry design, steel design, and depending on the building’s primary structural system, concrete, wood, or steel design. Therefore, shelf angle research in this area of masonry is often regarded as a “steel design” or “concrete design” problem, rather than a masonry design problem. There are few papers published on the topic and even less actual testing, with the experimental work to date focusing on shelf angles anchored to wood-frame floors. Complex interactions between the tied masonry veneer and the steel angle, as well as beam behavior of the brick veneer between anchor bolts are difficult to capture with models simple enough for hand calculations. A new design approach is proposed which more accurately accounts for the interaction between the tied masonry veneer and the shelf angle. The proposed design method more accurately reflects field observations of masonry veneer where a L102mm mm x 102mm x 6.4mm (L4in. x 4in. x ¼ in.) supports 7.315 to 9.144 m (24 to 30 feet) of 90 mm (3-5/8 in.) clay brick veneer without evidence of structural distress. This translates into a 5% to 8% cost savings on the shelf angle. The proposed design method uses the Force Method in combination with Virtual work to solve the 1-degree statically indeterminate system that results from the introduction of the tie restraining force at the first course of ties. This new method was then compared to the traditional statically determinate method as well as 2D and 3D finite element models. The proposed method also allows parameters like; veneer height, veneer type, shelf angle size and thickness, air space depth, and bolt hole location to be easily altered without the time-consuming effort of redrawing the system in finite element software.

KEYWORDS: Shelf Angle Design, Masonry Veneer, Deflection, Force Method, Virtual Work.

003-Hagel.pdf