P.R.A. Souza1 and G.A. Parsekian2

1 Former Master Student, 2 Professor ,

Department of Civil Engineering, Federal University of Sao Carlos, BRAZIL, parsekian@ufscar.br

ABSTRACT

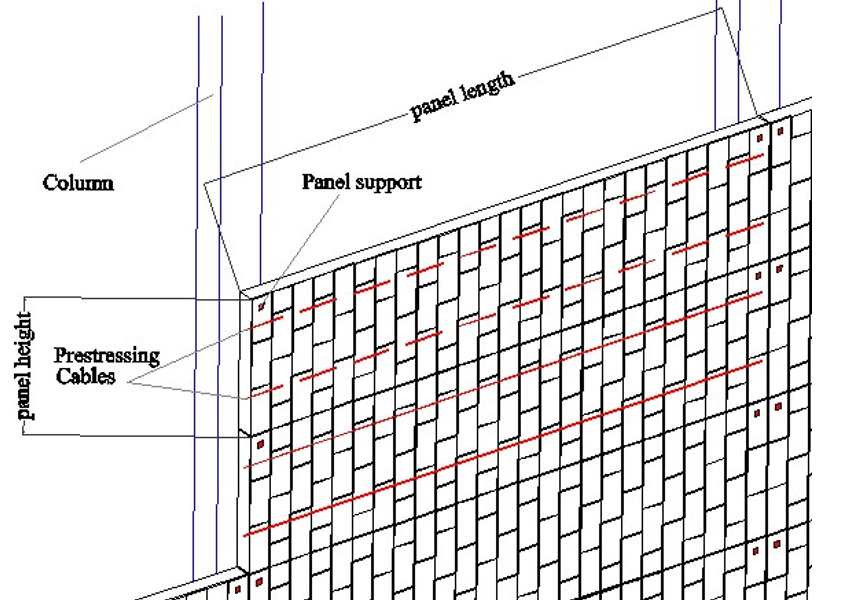

The widespread use of precast façade panels expedites constructions and increases their quality. Using such elements enables the construction process to be conducted on industrial scale. This paper reports on a study of clay block prestressed masonry panels as an alternative for the commonly prestressed or reinforced concrete façade panels. The panel was designed to bear regular winds loads and also tested for construction and transportation loads such as self-weight. The construction process was tested in two modes. First, several small vertical panels were built, after which they were rotated to the horizontal position and joined together by prestressed cables, forming a single 5-m long horizontal panel. In the second mode, the whole panel was built and prestressed horizontally. The two complete panels were then subjected to lateral loads in order to determine the failure load and displacements. The conclusions drawn from the tests were that both panels were able to bear loads close to predicted. Also both panels are expected to resist designing load in most practical cases

KEYWORDS: prefabrication; prestressed masonry; design

B2-5