Gheni, Ahmed1; ElGawady, Mohamed2 and Myers, John3

1 PhD candidate, Civil, Department of Civil, Architectural & Environmental Engineering, Missouri University of Science and Technology, 1401 N. Pine Street, aagmr6@mst.edu

2 Benavides Associate Professor, Department of Civil, Architectural & Environmental Engineering, Missouri University of Science and Technology, 1401 N. Pine Street, elgawadym@mst.edu

3 Professor and Associate Dean, Department of Civil, Architectural & Environmental Engineering, Missouri University of Science and Technology, 1401 N. Pine Street, jmyers@mst.edu

ABSTRACT

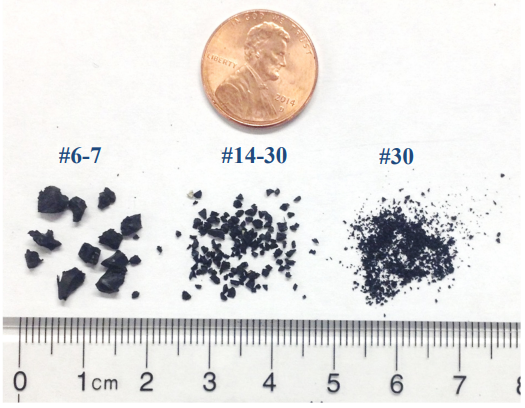

Replacing mineral fine sand in concrete masonry units (CMUs) with a scrap rubber potentially can improve the sustainability, strain, and ductility of masonry. An experimental investigation was conducted to explore the effects of adding different ratios of scrape crumb tiers rubber as an aggregate replacement to concrete masonry units. Replacement ratios of 0%, 10%, 20%, and 37% were investigated. Both grouted and ungrouted masonry prisms were subjected to an axial cyclic load. Different types of capping were also used and compared to obtain accurate stressstrain curves. More than 60 masonry prisms were tested under cyclic compression loads. Two prism heights, namely, two-block and four-block high were used to capture the axial strain in the masonry prisms. Using rubber did not have a significant effect on compressive strength of grouted prisms while it had significant effects on ungrouted prisms. For grouted prisms, replacing 10%, 20%, and 37% of mineral sand with crumb rubber decreased the compressive strength by 27%, 6%, and 30%, respectively. Furthermore, the results indicated the rubber significantly influenced the masonry ultimate strain and initial stiffness. Blocks having high rubber content displayed larger ultimate axial strains. The ultimate strain increased by 4%, 46% and 630% for 10%, 20%, and 37% rubber replacement. The effect of rubber on the post-peak strength and descending branch of the stress-strain curve was significant. Specimens having rubber exhibited a significant ductility. Failure of conventional specimens was quite brittle while specimens having rubber content displayed a high ductility. The mechanical characterization of the rubberized block showed that the new rubberized masonry units met the ASTM requirements for load-bearing concrete masonry units.

057