Keelson, Hannah1 and Zalok, Ehab2

1 MASc. Candidate, Carleton University, 1125 Colonel By Drive, Ottawa, ON, K1S 5B6, Canada,hannahkeelson@cmail.carleton.ca

2 Associate Professor, Carleton University, 1125 Colonel By Dr., Ottawa, ON, K1S 5B6, Canada, ehab.zalok@carleton.ca

ABSTRACT

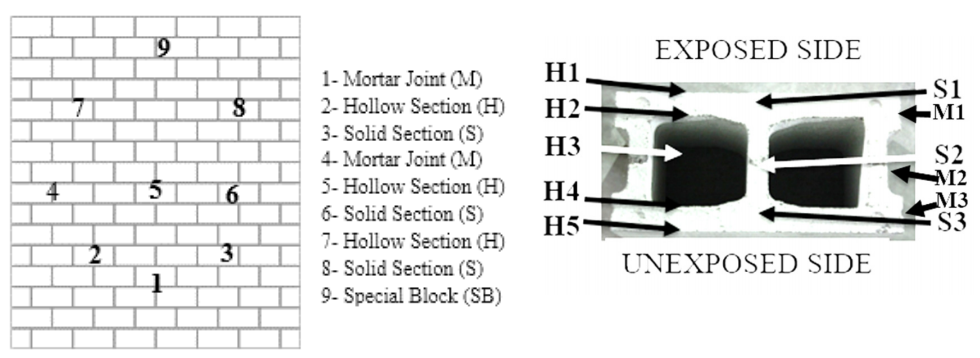

Prescriptive fire codes have been used to allow simple designs, but they come with many restrictions. Performance based codes on the other hand, attempt to provide clearer guidance than the prescriptive codes, taking into consideration all possible functional objectives that will affect the fire safety of a structure. These are usually guided by set objectives and are accordingly met by the designer. A full-scale fire test is usually required in the quest to provide these defined criteria for guidance in the use of performance based codes. However, a full-scale fire test is not always a practical solution as it is very expensive and needs a state-of-the art furnace with an appropriate fire capability. A computer simulation serves as an alternate option, for researchers to account for the effect of heat transfer on an element, assembly or a structure. The use of finite element (FE) modelling aids in the study of heat transfer and can be used to study the fire behaviour of a structure. This study focuses on modelling concrete masonry walls composed of normal weight concrete blocks and Type S Mortar with the aid of Abaqus/Standard 6.13. Results obtained from the fire model is compared with the experimental fire resistance tests, which has been conducted as part of an ongoing project. Mortar joints bond the masonry units of a wall together, and therefore play a significant role in affecting the overall appearance of these units. Raked joints are commonly specified for aesthetic purposes; however, they have been thought to reduce the fire resistance of masonry. One reason being that part of the mortar is scraped away from the joint at a consistent depth, which could cause joints to fail and allow for thermal bridging. Raked joints were modelled 0.5 cm deep on both sides of the wall. The typical concave mortar joint was used as a control in the analysis. Based on numerical results, and as confirmed by experimental results conducted earlier, both raked and full mortar joints produced similar fire resistance behaviour.

029