1 Assoc. Professor, Department of the Build Environment, Eindhoven University of Technology, Eindhoven, The Netherlands, a.t.vermeltfoort@tue.nl

ABSTRACT

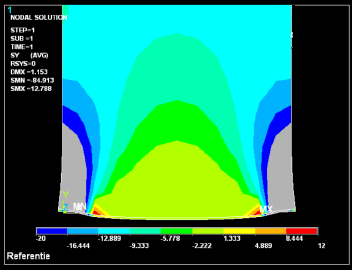

In load-bearing walls made of calcium silicate elements two types of joints can be recognized: joints between two elements and joints between wall and floor. Ideally, the mortar joints are completely filled and consequently stresses are transmitted uniformly through masonry. However, sometimes only the joint-edges are filled, like in shell bedded masonry. This causes irregularities in the stress distribution. Another situation with local contact effects where stresses are not uniformly distributed is the wall-floor connection when centering strips are applied. These strips are intended to concentrate the loads from the floor and to improve the floor wall interaction. To study the effects of such local contacts on the load bearing capacity of walls, 85 experiments and numerical simulations of these experiments were performed with parameters like the joint filling ratio and the width and position of the bearing strip. Relationships between the load bearing capacity and the main parameters were established.

KEYWORDS: bearing strip, local contact, face shell bedded masonry, splitting strength

261.pdf