Hagel, Mark1; Isfeld, Andrea2 and Rizaee, Samira3

1 Executive Director, Alberta Masonry Council, Suite# 205, 2725 – 12 Street NE, Calgary, AB, Canada, markhagel@albertamasonrycouncil.ca

2 Postdoctoral Scholar, Department of Civil Engineering, Schulich School of Engineering, 2500 University Drive NW, AB, Canada, acisfeld@ucalgary.ca

3 PhD. Student, Department of Civil Engineering, Schulich School of Engineering, 2500 University Drive NW, AB, Canada, srizaee@ucalgary.ca

ABSTRACT

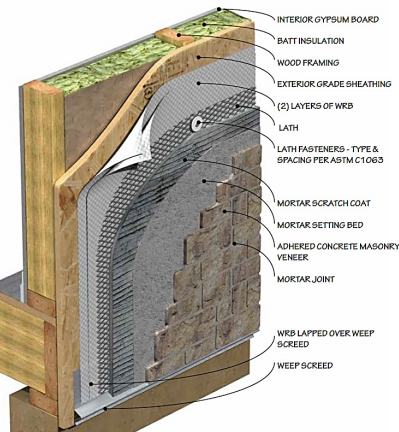

Thin masonry veneers individually secured by mortar adhesion have become increasingly popular in the North American construction industry. Some of the reasons include a reduction of

the cladding weight and a resulting reduction in the size and cost of the supporting structure, as well as speed and ease of construction. As the height of the adhered masonry cladding increases, however, the reliance on mortar bond to attach the thin masonry cladding to the support structure also increases and the greater the risk of damage to property or injury if that bond fails. In the past the CSA-A371-04 limited the height of these types of claddings to 3 m (10’) yet as these cladding have become more popular in commercial and multi-family residential construction veneer heights exceeding 3 m have become more common. The use of Type N and Type S in full bed masonry veneers are pre-dominantly relied upon in compression in the bed joint and to help mechanically anchor the veneer to the structural wall with ties. However, the use as the bonding mortar to adhere masonry places the mortar in both shear and tension. This paper explores a design method for adhered masonry veneer where the veneer heights exceed 3 m (10’) above grade.

113