S.N. Mihaljevic 1 and S.E. Chidiac 2

- A.Sc. Candidate, Department of Civil Engineering, McMaster University, Hamilton, ON, L8S 4L7, Canada, mihaljsn@mcmaster.ca

- Professor, Center for Effective Design of Structures, Department of Civil Engineering, McMaster University, chidiac@mcmaster.ca

ABSTRACT

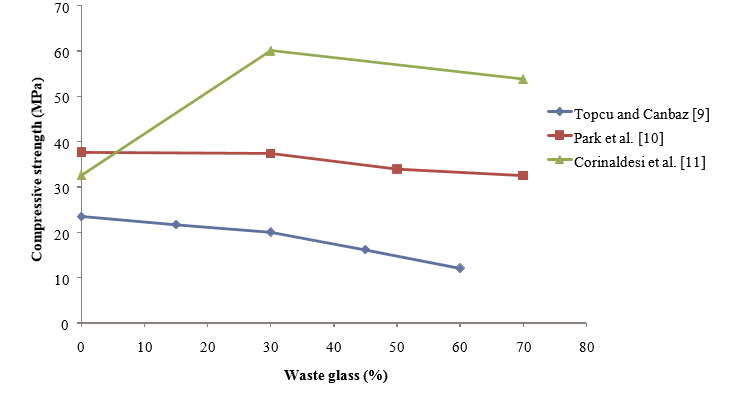

Concrete is the most widely used construction material, therefore reducing the environmental impact of concrete would greatly benefit the construction industry. The production of concrete, concrete blocks are no exception, requires the use of large quantities of natural resources, namely limestone, granite, shale and clay, and contributes to the production of carbon dioxide, in the manufacturing of Portland cement. Environmental benefits may be achieved by replacing a portion of the aggregate and cement with waste materials, such as glass and polymers, from postconsumer sources. It has been shown that glass can be used to replace a portion of the natural aggregate. Glass also is also being used as a supplementary cementing material. Furthermore, post-consumer polymer products, referred to as plastics, have been used as aggregate replacement in concrete. This paper provides a review of the research reported in the literature on the effects of using post consumer waste glass and plastics in concrete and concrete block production.

KEYWORDS: aggregate, cement, concrete, glass, plastic, pozzolan

C6-4