A realistic and fully costed comparison of different structural systems to determine how loadbearing masonry compares to wood frame and cast in palace concrete

A new study, conducted by local 3rd party firms, that compares the building structure costs for a multi-residential building typical of Atlantic Canada built with the following three materials: Loadbearing masonry, Wood frame construction, and Cast in-place concrete. The study conducted on behalf of the Atlantic Masonry Institute (AMI), was written by the Canada Masonry Design Centre (CMDC) and funded by the Canadian Concrete Masonry Producers Association (CCMPA).

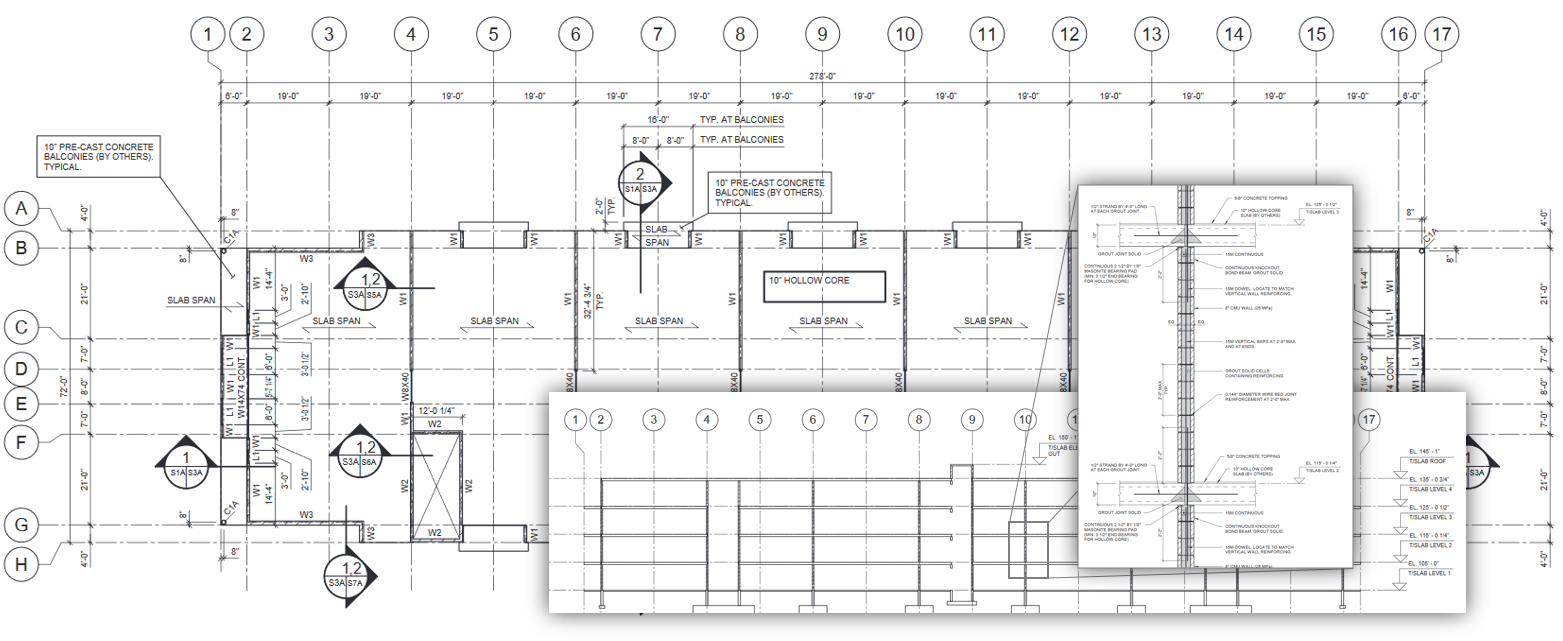

A floor plan was provided by local design firm Spitfire Design Co. for a prototypical 4-storey 55-unit building in Moncton NB. This floor plan was used to develop a structural design, completed by Valron Engineers Inc., for all 3 building material options both with and without underground parking. The building designs were then taken by Acadian Construction where construction schedules and cost estimates were conducted.

Key Findings

From the study, there were two important conclusions made when comparing the 3 building material options: scheduling and cost.

Advantages in scheduling

Loadbearing masonry has the fastest construction schedule and it’s not even close. For buildings with underground parking, the building can be erected and enclosed in only 28 weeks (50% faster than using wood frame construction and 64% faster than cast in-place concrete)

Not a large increase of initial cost from wood frame design to loadbearing masonry

A fully completed loadbearing masonry building is cost competitive with wood frame construction by only carrying a premium between 4% and 8%. When comparing to other non-combustible construction techniques, loadbearing masonry provides exceptional value by coming in 11% less than cast in-place concrete. Refer to the study for complete details on where these numbers came from.

Additional benefits for a small premium

The study follows up on these numbers by asking the question “Why is the small premium worth it?”, which can be summarized by the following points.

Building codes provide minimums. Masonry goes above and beyond for safety and comfort

Fire Ratings: Structural loadbearing masonry walls that use precast hollowcore planks have a high built-in fire rating. The walls and planks that are already used for structural purposes will provide >2+hours of Fire Resistance Rating (FRR). This will be more than double the code minimum value of 1-hour provided by wood frame construction. This is all in addition to the fact that concrete materials don’t burn, non-combustible building materials compartmentalize fires to limit their spread and do not provide additional fuel for the fire.

Sound Proofing: Structural loadbearing masonry walls that use precast hollowcore planks have a high built-in sound proofing or Sound Transmission Class (STC). The walls and planks that are already used for structural purposes provide STC ratings that start at 55 and can increase up to 73. Code minimums are an STC rating of 50, and to achieve this, the wood frame walls and floor system would require additional sound-proofing in the form of multiple layers of drywalls on each side of the walls.

Continued savings from ongoing insurance premiums

Concrete masonry buildings are less expensive to maintain and insure for a number of reasons. It does not rot over time. It also does not provide a source of food for mould to grow within the wall system. Lastly, in cases where there is exposure to water or moisture, there is not the same level of damage compared to wood frame construction. The improved resistance to moisture decreases insurance premiums for both Builders Risk, as well as Operating Insurance.

Reliable schedules from reduced construction delays

Concrete Masonry Units (CMU) are produced locally on demand. The raw materials used for the units, and the mortar, are readily available locally throughout Canada from multiple sources.

Full study and more information

A complete copy of the study can be viewed and downloaded using the link below:

Click here to view the full study

An alternate version with full sized appendix material can be found here

(this version contains varying page sizes)

Andrew Smith can be contacted with any questions or for more details regarding this study and its conclusions.